Mold Classifications and why you need to know them

Just like restaurants, not all molds are the same. Knowing a little about SPI mold classifications will help you choose, as it were, between the burger and the rib-eye.

Before 1978 these mold classifications didn’t exist, and there was confusion as to what constituted a Class A and Class B mold. The publication of “Classifications of Injection Molds for Thermoplastic Materials” by the Society of the Plastics Industry created a consensus for both mold makers and their customers.

The system is pretty simple. The following four factors will determine the class of mold you need:

- Your budget

- The plastic material you will be molding

- The number of parts you wish to make during the lifetime of the mold

- The complexity of the part you wish to make

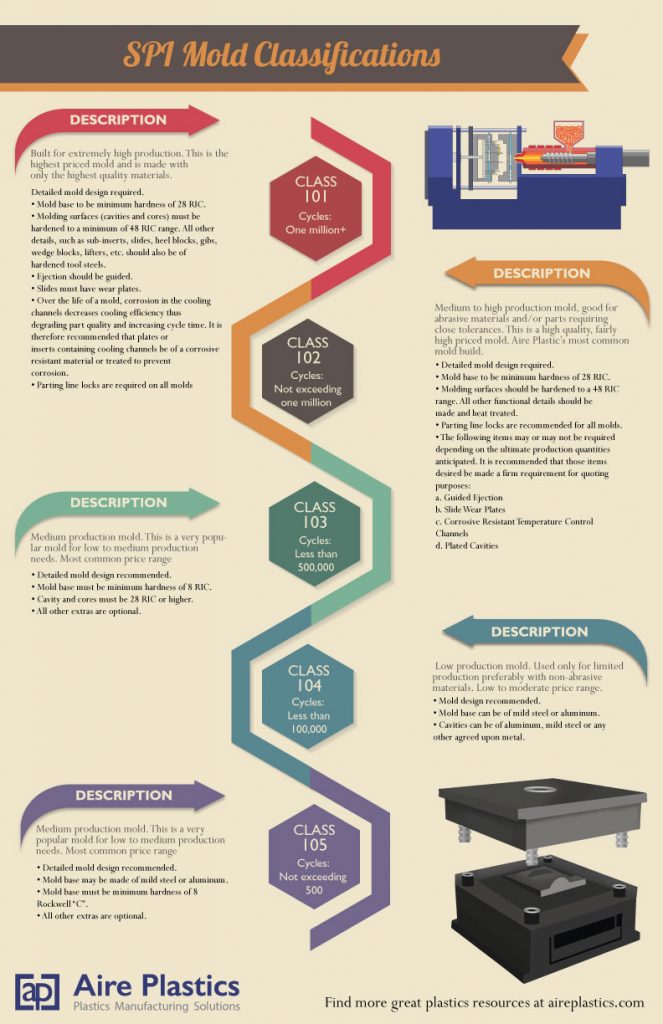

As you can see in the guide below, the standards cover only the materials used to make the mold and the number of cycles the mold should be able to handle. They do not address design details such as slides, gates, hot and cold runner systems, and so on, which can present problems throughout the lifetime of a mold.

Many other factors can affect a mold’s lifespan, such as maintenance and whether parts get closed in the mold, to name a few, but understanding the standard is a good place from which to start.

I’ve had customers tell me many times, “I got a cheaper price quoted from Company X on my molds. Can you tell me why?” My first response is usually to ask if the mold class is stated on the quote. And many times, I have been surprised to find that this very important detail is not listed.

I encourage all customers, whether they work with Aire Plastics or not, to require that the SPI Mold Classifications be listed on all mold quotes.

Here is the SPI Mold Classification Guide. You can also download a printable copy at the bottom of the page.

I hope this helps put the mold maker, the injection molder, and you—the product developer—all on the same page when quoting and building a plastic injection mold.