Plastic types: Nylon

Nylon: A Material with Legs

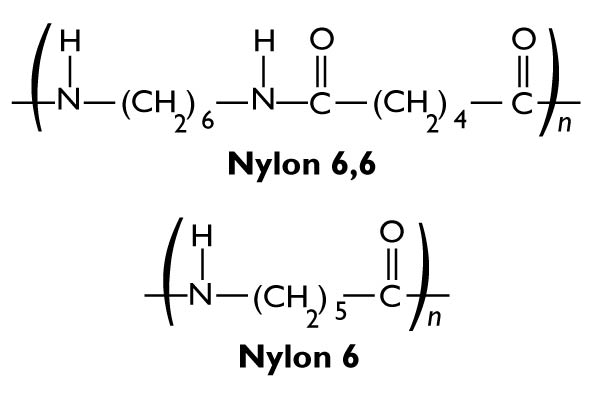

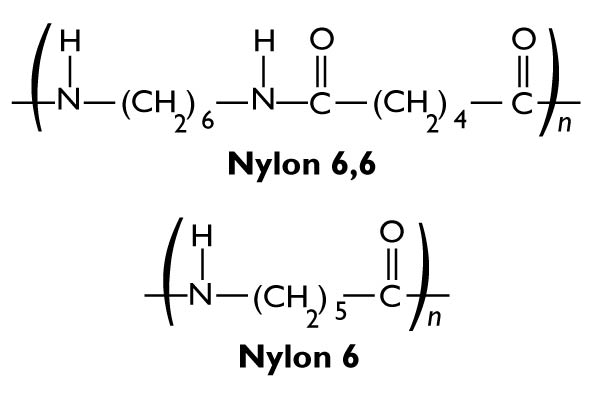

Nylon went into commercial production by DuPont in 1939. Like polyethylene and polypropylene—all plastics, really—it is made by polymerizing a simple chemical structure into long strands of repeating molecules.

Tough cookie: nylon’s properties

If you’re researching possible manufacturing materials, you’ll most often see two compounds: nylon 6 and nylon 6,6. When injection molded, both are amorphous, as opposed to crystalline, meaning that their chemical structure gives them good impact resistance and stability. Through mechanical stretching, however, nylon can be made highly crystalline, giving you nice smooth fibers.

It’s tough stuff, nylon, with excellent chemical, ultraviolet, and wear resistance. Glass can be added to Nylon to add to its toughness. There is even a supertough, or ST, class of nylons, recommended for products that are destined for long lives of high, repeated impact.

Nylon manufacturing and recycling

All types of Nylon are technically recyclable, but some of the processes are difficult and expensive. In injection molding, we can regrind different grades of Nylon and mix with virgin material at low percentages (10-20%). Aleast 60 percent of nylon’s use is in fibers and because nylon is so durable, the products that are made from it last for years and are not thrown away with the same frequency as other plastics. Reusable shopping bags, backpacks, suitcases, outdoor clothing, and other nylon fiber products get a lot of long use and can be repaired as well as donated to ensure they stay out of landfills for many years.

Several forward-thinking companies, including Patagonia, carpet maker Aquafil, and Bureo are creating closed product loops or specifically sourcing recycled nylon for their raw material. Bureo pays Chilean fishers to collect old nylon fishing nets (which are filling the world’s oceans), which it then turns into sunglasses and skateboards. Aquafil’s carpets become new fibers, sold under the name Econyl, that can be made into clothing. Speedo is now using Econyl in more than 50 products.

If you’re designing a product that has fibers, needs incredible strength and durability, or both, you probably have some nylon in your future.

For more info, check out these links:

https://en.wikipedia.org/wiki/Nylon_66

http://www.polymerprocessing.com/polymers/PA66.html

Jenifer Wolfe

Consulting Editor

Jennifer Wolfe has a curious mind and a gift for words and languages—if she does say so herself. A trained metalsmith and lifelong craft nerd, she loves handmade stuff, whimsical clothes, and traveling. A resident of Mexico, she is certain that tacos are the food of the gods.