Plastic Types: Polypropylene

Plastic Types: Polypropylene

We start with PP because it’s one of the most in-demand plastic materials in the world. Polypropylene belongs to the thermoplastics

What is polypropylene?

Polypropylene was developed in 1954 by German and Italian chemists and quickly became the family’s golden child thanks to its many talents: PP is now a significant component of everyday items from banknotes and baby wipes to medical equipment.

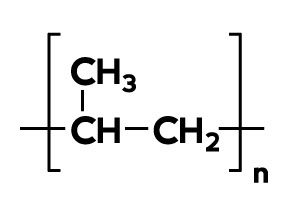

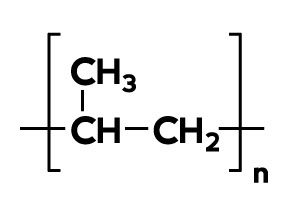

The base, propylene, is produced partly as a by-product of fluid catalytic cracking, or FCC, the same process that derives gasoline and gases from crude oil. When propylene goes through a polymerization process—linking together many of its simple carbon-hydrogen structures into bigger structures—it becomes polypropylene.

PP’s superpowers

This plastic is unique in its ability to be heated, shaped, and cooled many times over without losing its structural integrity. PP is extremely durable, has high chemical resistance, and can take a wide variety of finishes and surface treatments. Like other plastics, it can take on many forms: It gets extruded, poured, and injected. In fact, polypropylene is the material for injection molding.

Because PP is easy to manipulate and tool, it costs less to prototype and manufacture with than other materials. It is also a “low density” material so is good for products that need to be light in weight.

In the process of making PP, producers can use additives or modify the molecular structure in order to give PP certain qualities. Here are the most common grades and uses:

Homopolymer polypropylene: You know that feeling when you open the dishwasher and see a misshapen “reusable” container? That won’t happen with products made from homopolymer PP. The native state of PP, this resin is highly rigid and has a melt point of 160°C (320°F), making it particularly suitable for products that are likely to be used in microwaves or that need steam sterilization, for example. Its hardness, however, makes it brittle and prone to breakage at low temperatures, so you don’t want it for your new ice tray design.

Random copolymer polypropylene: This grade is softer and has a lower melting temperature. It doesn’t break or crack as easily as homopolymer PP and is resistant to chemical and environmental damage. So you might consider it for certain types of toys but probably not for kitchenware.

Block copolymer polypropylene: This material can withstand freezer-to-microwave temperatures without damage, but doesn’t have much range in the looks department: it is always cloudy to opaque. Aesthetic design is an important consideration in any product, and you’ll have to weigh the twin factors of form and function.

As you’ve seen by now, polypropylene is incredibly flexible. In its extruded or sheet form, it can become a component of face masks, diapers, plastic films of varying thicknesses and uses, and those baby wipes we mentioned. It can be turned into fibers as well, for use in rope, carpets, and even textiles. When injection molded, the resin can transform into cups, cutlery handles, microwavable lunch containers, car battery casings, lab equipment, and bottles for lotions, liquids, and pills. And these are the short lists.

One interesting note is that polypropylene is a good material for products that have an integrated hinge, called a living hinge, which is a hinge that is made of the same material as the container itself (so, almost every flip cap ever).

Use, recycle, reuse, repeat

If you’ve seen community programs in which yogurt cups were made into, say, a park bench, you’ve seen recycled polypropylene at work. In the early days of recycling PP, some companies created their own collection programs, including hair product maker Aveda and toothbrush maker Preserve. Now, recycling PP products is much easier in the United States, with many facilities now accepting them (a number 5 stamp lets you know a product is made from PP).

To learn more about Polypropylene check out these links:

Society of Plastics Engineers (SPE) Materials Database

Plastic Injection Molding: Material Selection and Product Design Fundamentals

Jenifer Wolfe

Consulting Editor

Jennifer Wolfe has a curious mind and a gift for words and languages—if she does say so herself. A trained metalsmith and lifelong craft nerd, she loves handmade stuff, whimsical clothes, and traveling. A resident of Mexico, she is certain that tacos are the food of the gods.