SPI Mold Finish Guide and Guidelines

Today let’s take a look at the SPI mold finish guide and guidelines, so you can understand why they’re important and what their limitations are. This, of course, is just a primer. You need to discuss SPI mold polish types with your DFM engineer, as the polish of your mold will affect both the mold performance and the function of your product.

As I’ve said over and over and ooover again, until your ears were bleeding and your eyeballs were popping out of your head: Taking a close look and documenting every detail of your design and tooling requirements will help avoid a lot of angry conversations, disappointments, and even legal battles. The foundation of your project is…the tooling (queue the scary music).

As you probably already know, SPI stands for the Society of the Plastics Industry. The SPI mold finish standards are pretty straightforward. Samples of each polish type can be purchased through the SPI store; search for AR-106 Mold Polish Guide. For $20 you get samples of each polish type on a nifty plastic page.

Your DFM engineer should have a SPI Mold Finish Guide on hand so together you can come up with the best option for your project. That said, remember that polishing requires a human to sit for days hand-polishing your mold, which may incur added costs. Just keep that in mind if you’re inclined to ask to see your beautiful reflection in every part.

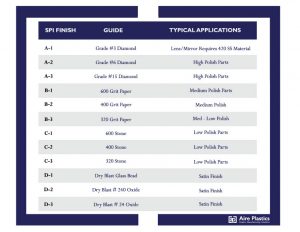

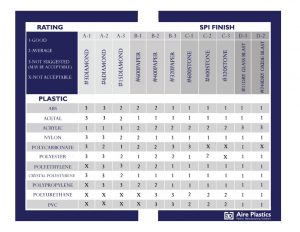

Since we still don’t have the sensation of touch (or smell, thank God) on the Internet, here are two charts that explain the basics. The first chart explains each polish type, and the second explains which type is recommended for molding different plastics.

Printable SPI Mold Finish Guide and Guidelines

Need to print it? Download Free PDF’s of these Charts. Printable on 8.5″ x 11″ Standard Letter Paper.

When placing a surface call out on a plastic part print should the SPI finish be used or the roughness values (µm) be used.

Hi Ken, Yes, usually our DFM Engineers make the SPI finish call out on a 2D drawing with critical tolerances and details such as polish AND on the 3D models with the textured areas colored per texture type and notated.